Marché

Cheese commander pro spare spring (2)

The Cheese chopper Pro is the wire cutter for cheese specialists.

This cutter cuts every type of cheese down to size and is especially suited to soft cheeses.

What makes this cutter so exceptional is the special mechanism behind the wire.

It has an improved guidance mechanism, thus reducing the chances of wire breakage and increasing the ease of cutting in one smooth movement.

The ergonomic grip makes the sturdy wire easy to handle, and the wire length is optimized for ease of use.

Boska also devoted extra attention to the replacement of the wire.

If it happens to break, it can be easily replaced by one of the six spare wires included.

Just pop it in no tools required.

The Cheese chopper Pro is equipped with an anti-slip base, so it won t drift around on a smooth work surface.

You can choose from two types of feet enclosed in the package:

rubber and suction cups.

The device has a compact shape and the positioning of the feet can be adjusted which allows it to fit on virtually every counter.

The frame is made of super thick plastic, and it has stainless steel wires, making it extremely durable, strong, food-safe, and dishwasher-safe.

In short it s super convenient.

Compact wire cutter Suitable for all cheeses New guidance mechanism less wire breakage and it s easier to cut Easy wire replacement Includes two types of anti-slip feet Fits on every counter Includes six spare wires Made of super-strong plastic so it s durable and dishwasher-safe

Single handle knife Pro 360 mm

The special knives from the Pro-Series are the result of years of Boska Holland s experience in cheese slicing.

For every sort, hardness and structure there is an appropriate knife.

The high handle ensures that your hand stays clear of the cutting board while cutting.

Matrix Mono paper

This premium cheese paper increases moisture exchange to guarantee the consistency of taste and texture throughout the product lifecycle, resulting in extended shelf life and delivering the right taste to consumers.

Matrix is also recyclable in practice where collection and recycling streams exist.

Sold by 500 sheets.

Polyflex white

It's the perfect wrapping solution both for commercial or domestic use. Polyflex allows air exchange and longer shelf life.

Thanks to its interior coating, you can now keep aromas where they are meant to be.

Each package contains 500 sheets.

Stainless steel aging rack 630 x 510 mm, 51 wires, H120/100 mm

For a homogeneous rind development

The racks are assembled in stacks, leaving sufficient space for uniform ventilation of each cheese.

Racks constructed from stainless steel wire are a flexible solution that optimizes space in the factory, from storage to use.

Our wire stainless steel aging racks are used for ripening, brining and drying cheeses allowing an optimal ventilation and support of the products.

The choice of rack size should be done according to the cheese size and type.

They stack legs on legs to create shelves where the cheeses can be placed.

This modular solution will optimize the space in the room allowing an even result and an easy manipulation.

It suits well for fresh, soft and semi-soft cheeses, blue cheeses and other varieties that need to ripen or dry.

Made in #304 SS.

Assembly of the wires on the frame by food-grade spot welding.

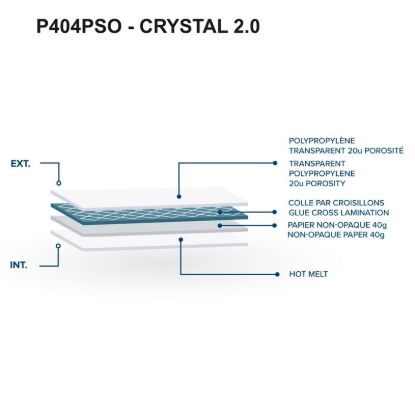

Crystal 2.0

Multi-layer packaging with a translucent paper and a clear polypropylene layer.

A patented Alize porosity treatment is allowing a homogeneous permeability.

Heat-sealable.